Isn't ultraviolet light invisible? How did the colorful UVLED come?

发布时间:2021-06-01 17:31

来源:萤光创新

UVLED can be divided into UVC, with peak wavelength (WLP) in the 200-280nm band; UVB in the 280-320nm band; UVA is in the 320-400nm band. Among them, UVB and UVC band ultraviolet light itself is invisible to the naked eye, but many UVC chips will emit light visible to the naked eye, the light is blue, purple, white, yellow, etc., there are different light colors. This problem is not obvious in blue-green LED, mainly because blue-green LED operating state brightness is very high and the wavelength change caused by the visual light color difference is small, but in UVLED application is very common or even unavoidable.

However, blue-green LED is mainly used for lighting, backlight, landscape, etc., and visual observation is an important basis for evaluating its advantages and disadvantages. However, UVLED chips are mostly functional applications, and the evaluation is based on functional realization, so the problem of different light colors is not the main problem faced by UVLED.

But even so, the problem of different light colors of UVLED still needs in-depth analysis. The light color is usually greatly affected by the epitaxial structure. The following is to analyze the mechanism of epitaxial materials for the light color problem of UVLED.

The direct cause of the different colors of visual light is the different spectrum

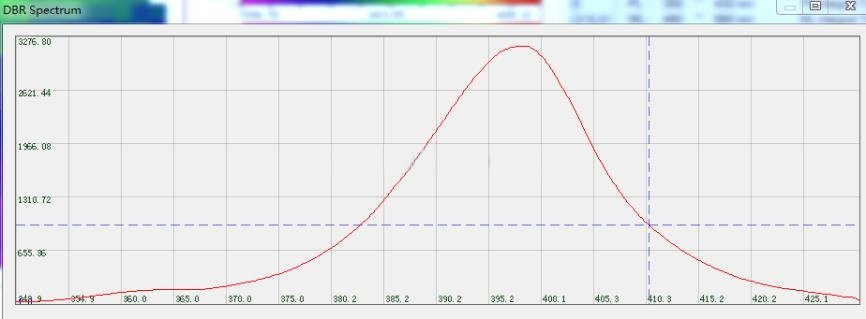

At present, the mainstream wavelength peak (WLP) of UVC LED is 270nm-280nm, and its spectrum is shown in Figure 1. The highest peak is 278nm, and both sides gradually decrease. In the direction of long wave, when the wavelength reaches the visible light range of 380nm or above (purple circle), there is still a certain intensity, this part of light will be received by the human eye, showing faint purple light; If the wavelength reaches 460nm (the blue circle) and has a certain intensity, it will appear as a faint blue-violet light. If the intensity of the blue light region approaches or even exceeds the intensity of the violet light region, it appears as a faint blue light.

图一 UVC芯片光致发光谱

(A) half width of spectrum

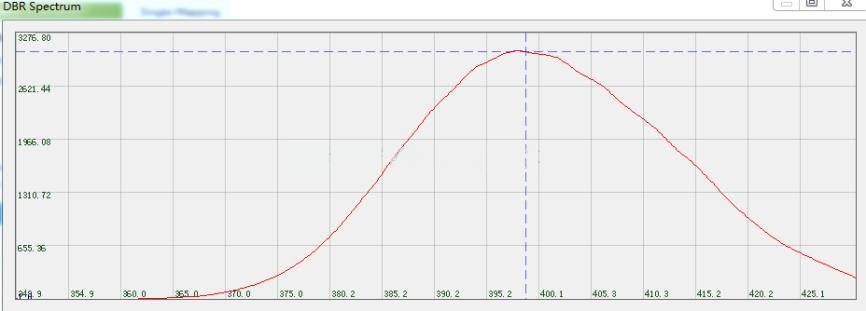

The UVA band is the main band that affects the light emitting color of chip. Blue and green are all visible light and the brightness is very high, UVC and UVB light is not visible, UVA is part of the light to visible light, the proportion of visible light largely influence the emitting light colors, so the UVA and a half wide band spectrum for emitting light colors effect more apparent, as shown in figure 2 (a), and a half high width (FMHW) is small, light color will be purple; In FIG. 2 (b), the spectrum FMHW is larger, and the luminous color will be blue.

Similarly, the size of FMHW will also be reflected in the main wavelength data. In most cases, the larger FMHW is, the larger the main wavelength will be, and the glow color will be longer wavelength.

Figure 2. A is small in half width and purplish in color

FIG. 3 Photoluminescence spectra of different half-widths of spectra (b spectrum is half-wide and the luminescent color is bluish)

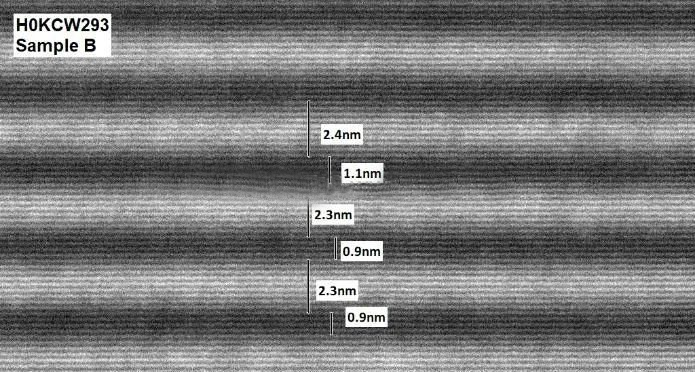

The well width of quantum well is one of the factors that determine the luminescence spectrum. The deviation of process control will lead to the change of well width, such as temperature, saturated vapor pressure of MO source, group III element composition and other factors will lead to the change of growth rate, which will lead to the change of well width. If the well widths of different positions in the material are significantly different, or the well widths of different epitaxial layers at the same position are significantly different, the problem of half width of the spectrum will appear. In addition, the doping of trap layer and polarization field can also cause the problem of half width of the spectrum.

Figure 4. Image of wide wave transmission electron microscope

(2) luminescence from deep energy levels

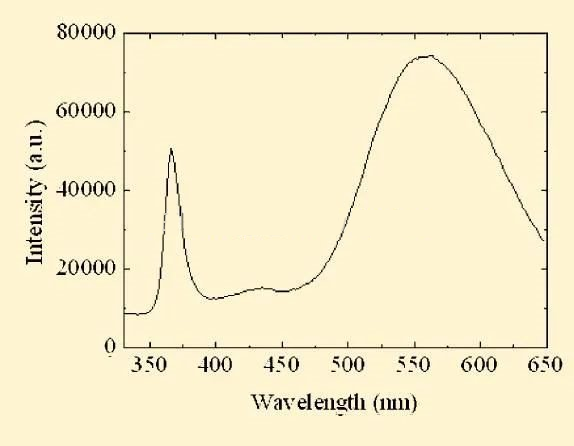

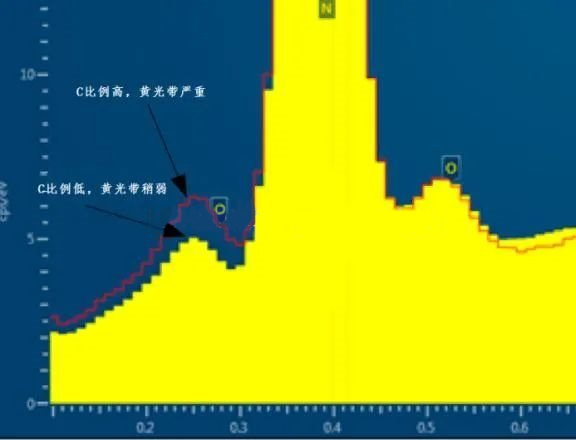

In LED products made of group III /V compounds, the yellow light band always exists in the spectrum of blue-green LED, violet LED, UV LED and other chips. Its wave peak is around 550nm and its intensity is very low. However, the human eye has the strongest sense of 550nm wavelength, so the yellow light band is easy to be captured by the human eye.

The operating wavelength of UVC products is not visible to the naked eye, so the yellow band will be more easily captured, making the product appear faint yellow light. The origin of the yellow bands has never been definitively determined.

Figure 5. Yellow band spectrum of UVA chip

There is no absolute correlation between the intensity of yellow light perceived by the naked eye and the brightness of the chip. The stronger the chip's luminescence, the stronger the light emitted by the yellow band excited by the short wavelength; At the same time, the yellow band absorbs too much of the working wavelength.

(Key) : If the intensity of the yellow band is high, the chip glow color will directly show yellow; If the yellow band is low in intensity, well below the blue and violet parts of the spectrum, then the yellow will mix with the blue and violet to produce white light.

The above luminous color differences caused by the spectrum can mostly be reflected in the main wavelength data. The main wavelength of the chip with purple luminous color should be below 430nm, the main wavelength of the chip with blue luminous color should be above 450nm, and the main wavelength of the chip with yellow luminous color may reach 500nm.

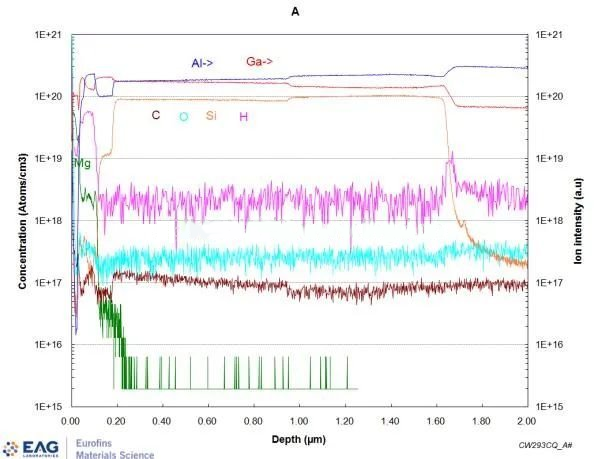

Many studies have attributed the origin of yellow bands to deep energy levels, among which Ga vacancies, Mg and C have attracted the most attention [1,2]. For example, C pollution, because the metal source used in the growth process is organic matter, it is inevitable that C atoms will enter the material, and such C atoms will either combine with N atoms or enter the gap to form deep C energy level and provide the light source of the yellow band. Secondary ion mass spectrometry (SIMS) and X-ray energy spectrum (XPS) test analysis showed that the density of C in the material was still very high, reaching 1E17cm-3. In general, the yellow band is more obvious in materials with a larger proportion of C.

FIG. 6 SIMS and EDS data of different c-component materials

In addition, the blue band luminescence associated with Mg doping is also common in LED. Some studies show that the deep level of Mg in P-gan is located at the bottom of the GaN conduction band -0.2eV, so the spectrum is about 390nm, so that the UV LED chip, especially the UVC LED chip, will show blue-purple light color.

In addition, there are some impurities, gaps and other defects [3-5], such as Fe impurities, Ga interstitial atoms, H complexes, organic molecules, etc., as well as some C gaps or complexes. Most of these defects are difficult to be captured by conventional test analysis, but they are also unavoidable in the growth process of MOCVD. The results show that these defects form two obvious deep level bands in GaN materials. One level is located at the bottom of the GaN conduction band about -0.5eV, and the peak of the luminescent wave is between 420nm-440nm. The effect of this defect on the luminescence color is more obvious, UV LED chip is affected by this deep level luminescence, the luminescence color will appear blue purple or blue. The other is located in the yellow band spectrum and is thought to be one of the causes of the yellow band.

文章出自:材料深一度

文章关键字:UVC、UVC LED、深紫外、紫外杀菌、深紫外 LED、水杀菌、空气杀菌、流动水杀菌